No products in the cart.

Thermocoat WI

Thermoguard Thermocoat WI

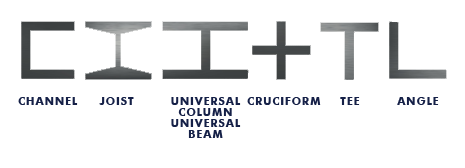

Thermoguard Thermocoat WI is a high-performance, water-based intumescent paint system designed to provide up to 90 minutes of fire resistance for structural steel and cast iron with a minimal number of coats. This product is optimized for use on Universal Beams, Columns, and other open section steel structures. For steel hollow sections, consider Thermoguard Thermocoat WO Ultimate. For exterior environments, Thermoguard Thermocoat S is recommended.

From £84.00 Incl. VATFrom £70.00 Excl. VAT

Thermocoat WI

From £84.00 Incl. VATFrom £70.00 Excl. VAT

Product Overview: Thermoguard Thermocoat WI

Economy and Speed

Thermoguard Thermocoat WI is a high-performance, water-based intumescent paint system designed to provide up to 90 minutes of fire resistance for structural steel and cast iron with a minimal number of coats. This product is optimized for use on Universal Beams, Columns, and other open section steel structures. For steel hollow sections, consider Thermoguard Thermocoat WO Ultimate. For exterior environments, Thermoguard Thermocoat S is recommended.

Key Features:

- Economical: Designed for larger projects with technical support for precise quantity requirements, minimizing costs.

- User and Environmentally Friendly: Low odor, water-based formulation compliant with 2010 safety regulations.

- Enhanced Aesthetics: Compatible decorative overcoat system available to enhance architectural and design features.

How it Works

Thermoguard Thermocoat WI reacts to fire by expanding into an insulating char layer up to 50 times its original thickness. This char layer acts as a thermal barrier, preventing the steel from reaching its critical failure temperature, thus maintaining the structural integrity of the building during a fire.

Fire Testing

Thermoguard Thermocoat WI’s performance is assessed and certified by UKAS/EGOLF accredited Fire Test Laboratories according to BS 476 Part 21 standards, which evaluates fire resistance for load-bearing structural elements.

Fire Certification

Upon project completion, a Certificate of Supply can be issued upon request for each specified project. This certificate is essential for insurance purposes, Fire and Building Control Authorities, and Client Records.

Preparation and Pre-Treatment

Steel and Cast Iron Preparation:

- Surfaces must be free from rust and millscale.

- Prime with Thermoguard Steel Fire Paint Primer at a thickness of 75 microns DFT or use a compatible high-quality anti-corrosive primer.

Galvanized Surfaces:

- Treat with Teamac Mordant Solution (T Wash) before priming with Thermoguard Steel Fire Paint Primer.

Priming:

- Thermoguard Steel Fire Paint Primer can be left uncoated or decorated with conventional paint if no fire resistance is required.

Specification

Protection Levels:

- Dry Internal Areas: Apply Thermocoat WI according to the film thickness schedule provided by the Technical Department for 30, 60, or 90-minute fire protection.

- Modest Damp Internal Areas: Apply one coat of Thermoguard Flame Retardant Topcoat (available in Gloss or Eggshell finishes).

- Wet or External Under Cover: Apply a second coat of Thermoguard Flame Retardant Topcoat.

- Full External Exposure: Contact the Technical Department for specific guidance.

Application

Methods:

- Brush, Roller, or Airless Spray: Spray application is recommended for the best finish and quickest application.

Film Thickness:

- Brush Application: Maximum 800 microns per coat.

- Spray Application: Maximum 1400 microns per coat.

Application Tools:

- Use a wet film gauge to ensure correct film thickness. Wet film gauges are available on request from the Technical Department.

Recoating

Brush/Roller Application:

- Surface Dry: Minimum 2 hours

- Recoat: Minimum 4 hours

- Overcoat with Flame Retardant Topcoat: Minimum 10 hours

Spray Application:

- Surface Dry: Minimum 4 hours

- Recoat: Minimum 10 hours

- Overcoat with Flame Retardant Topcoat: Minimum 48 hours

Spray Equipment

Recommended Equipment:

- Airless Spray Pump: Use equipment recommended by the manufacturer for high viscosity intumescent paints.

- Filter Size: 30 mesh

- Hose: 10mm, 3/8” diameter with no whip end

Tip Sizes:

- Use tips 319, 321, 419, or 421. Regular cleaning of filters is necessary. Clean filters and equipment with water.

Application Conditions

- Maximum Relative Humidity: 80%

- Minimum Ambient Temperature: 4°C

- Minimum Steel Temperature: 3°C above Dew Point

Terminology

Steel Types:

- CHS: Circular Hollow Section

- SHS: Square Hollow Section

- RHS: Rectangular Hollow Section

For further technical details and support, please contact the Thermoguard Technical Department.

| Size | 2.5kg White, 5kg White, 20kg White |

|---|